What Are the Core Design Features of the Normal Trigger Sprayer That Distinguish It in the Market?

The ergonomic handle design of the

Normal Trigger Sprayer manufactured by Zhejiang EAED Technology Development Co., Ltd. is a critical feature that enhances user comfort and operational efficiency. The company, located in the historic city of Yuyao, prioritizes human-centered design to reduce hand fatigue and strain during prolonged use. The handle shape is meticulously contoured to fit naturally in various hand sizes, ensuring that the sprayer can be comfortably operated by a wide range of users. This design consideration is especially important in professional settings such as cleaning services, agriculture, and personal care industries, where repetitive spraying actions are common. Beyond shape, the trigger mechanism offers optimal resistance and smoothness, allowing users to deliver a controlled amount of liquid without requiring excessive force. A non-slip surface on the trigger further enhances grip, even when hands are wet or gloved, reducing the risk of accidental slips that could disrupt the spray pattern or cause spills. This attention to detail in handle design is a direct result of EAED’s dedication to fine management and innovation, reflecting the company’s understanding that usability directly impacts customer satisfaction and productivity. The handle’s design also incorporates durability considerations, using materials that resist wear and deformation despite repetitive mechanical action. By focusing on ergonomics and functionality, Zhejiang EAED Technology Development Co., Ltd. ensures that their Normal Trigger Sprayers provide a reliable, comfortable experience, distinguishing them from competitors whose products may prioritize cost over user experience.

The choice of materials used in Zhejiang EAED Technology Development Co., Ltd.’s Normal Trigger Sprayers is a defining factor in their market distinction. The company sources premium-grade polypropylene (PP) and polyethylene (PE) plastics, known for their outstanding chemical resistance, tensile strength, and durability. These materials enable the sprayers to handle a wide variety of liquids, including corrosive cleaning agents, pesticides, disinfectants, and cosmetic formulations, without degradation or leakage. EAED’s proximity to major international ports like Shanghai and Ningbo facilitates access to high-quality raw materials, ensuring that the sprayers comply with international safety and environmental standards. The chemical resistance of the sprayers prevents interaction between the liquid contents and the sprayer components, which is essential to maintaining the integrity and effectiveness of the sprayed products. For example, in agricultural applications, a chemically resistant sprayer can withstand exposure to harsh pesticides without weakening or contaminating the chemical solution. In addition to chemical compatibility, the materials selected exhibit excellent resistance to UV radiation and temperature variations. This property is crucial for outdoor uses, where prolonged exposure to sunlight and varying weather conditions could otherwise compromise the structural integrity of lower-quality sprayers. Zhejiang EAED Technology Development Co., Ltd.’s material choices reflect a commitment to sustainability by extending the lifespan of their products, thereby reducing replacement frequency and environmental waste.

The precision nozzle system is a standout feature of the Normal Trigger Sprayer, engineered to provide versatility and control in spray delivery. Zhejiang EAED Technology Development Co., Ltd. has developed nozzles capable of producing a wide range of spray patterns, from fine mists to focused streams, meeting diverse customer needs. This capability is critical across industries such as household cleaning, horticulture, and personal care, where different applications require varying droplet sizes and spray distributions. The nozzle includes an intuitive adjustment mechanism that allows users to switch spray patterns easily, offering flexibility without sacrificing performance. This feature prevents waste and overspray, enhancing efficiency and safety, especially when applying chemicals or sensitive liquids. Internally, the nozzle geometry is carefully optimized to produce consistent atomization, reducing clogging and ensuring reliable operation even after repeated use. Zhejiang EAED Technology Development Co., Ltd.’s design approach reflects their collaboration with brand customers who demand high-performance sprayers tailored to specific application requirements. This design sophistication distinguishes EAED’s product in the marketplace by enabling end-users to achieve precise application results and maximizing product effectiveness.

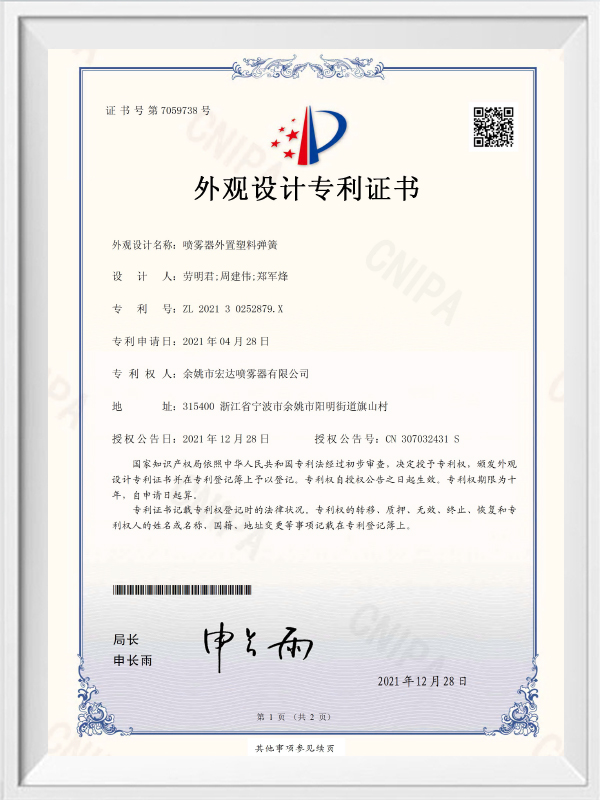

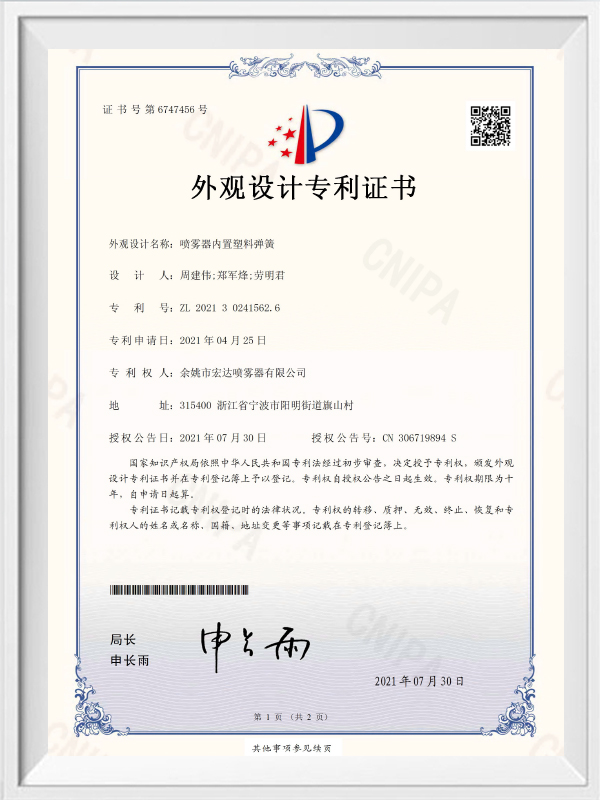

The internal pump mechanism of the Normal Trigger Sprayer is crafted with engineering precision to deliver consistent and reliable performance. Zhejiang EAED Technology Development Co., Ltd. focuses on minimizing friction and mechanical wear through the use of high-quality springs and tight manufacturing tolerances. This attention to detail ensures that each trigger pull produces uniform liquid flow, a crucial factor for users relying on predictable spray output in professional or industrial contexts. The pump incorporates a one-way valve system that prevents backflow, maintaining product hygiene and protecting the liquid contents from contamination. Rapid priming capabilities allow the sprayer to deliver spray immediately after periods of inactivity, an important feature in applications requiring intermittent but timely spraying actions. These mechanical features combine to improve user satisfaction by eliminating common issues like inconsistent spraying or pump failure. The pump’s smooth operation also reduces noise and mechanical resistance, improving comfort during extended use. Zhejiang EAED Technology Development Co., Ltd.’s rigorous quality management processes ensure these performance characteristics remain consistent across production batches, supporting the company’s reputation for reliability. Such robust engineering elevates the Normal Trigger Sprayer above many competitors whose pumps may suffer from uneven performance or premature failure.

Zhejiang EAED Technology Development Co., Ltd. integrates secure closure systems into their Normal Trigger Sprayer design to prevent leaks and accidental discharge. The sprayers feature precision screw caps with tight threading that form a robust seal between the sprayer and bottle neck, effectively eliminating leakage during transport, storage, and use. This design aspect is particularly important in industrial and commercial contexts, where spillage can lead to product loss, contamination, and safety hazards. The sprayers include trigger locking mechanisms to prevent accidental activation. The locking system is designed to be easily engaged and disengaged without compromising operational readiness, combining safety with convenience. This anti-leakage focus reflects Zhejiang EAED Technology Development Co., Ltd.’s commitment to creating reliable, user-friendly products that anticipate real-world usage scenarios. By addressing these safety and practical concerns in the design phase, EAED enhances customer trust and product reputation in both domestic and global markets.

The notable market advantage of the Normal Trigger Sprayer from Zhejiang EAED Technology Development Co., Ltd. is its compatibility with multiple bottle neck sizes and finishes. The company produces sprayers that fit common industrial standards such as 24/410 and 28/410 neck finishes, which are widely used across different packaging applications. This compatibility facilitates seamless integration into existing packaging lines without the need for costly adjustments or special containers. The precision engineering and quality control at EAED ensure that the sprayer’s thread dimensions and sealing surfaces meet strict tolerances, providing secure fit and leak-proof connections. This versatility supports a broad customer base, from manufacturers of household cleaning products to agricultural chemical formulators, who require adaptable packaging solutions to meet diverse market needs. The ability to accommodate various container types without compromising seal integrity or spray performance distinguishes EAED’s Normal Trigger Sprayer as a flexible and customer-oriented product. This adaptability not only improves supply chain efficiency but also enhances end-user convenience by allowing easy replacement and interchangeability.

English

English русский

русский Français

Français Español

Español italiano

italiano