How Does the Internal Spring Mechanism Enhance Product Safety and Shelf Life Compared to External Spring Alternatives?

One of the most fundamental design elements of an

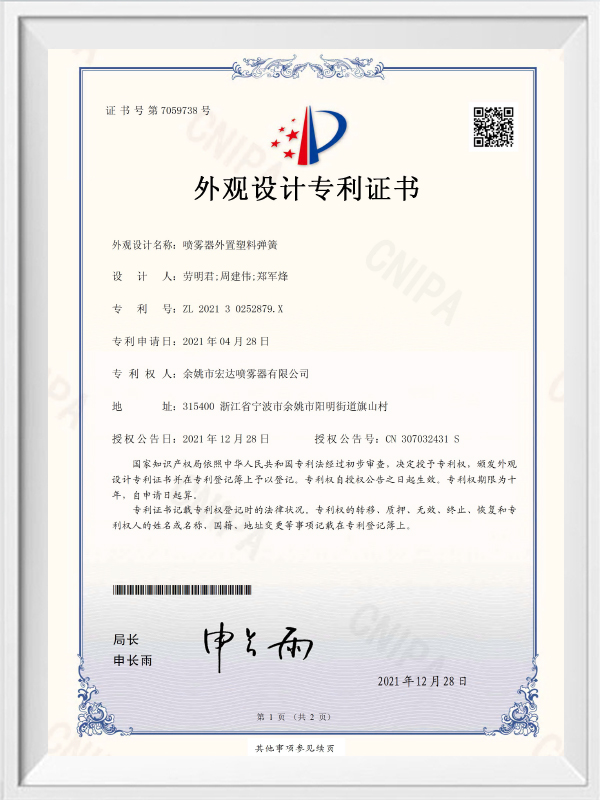

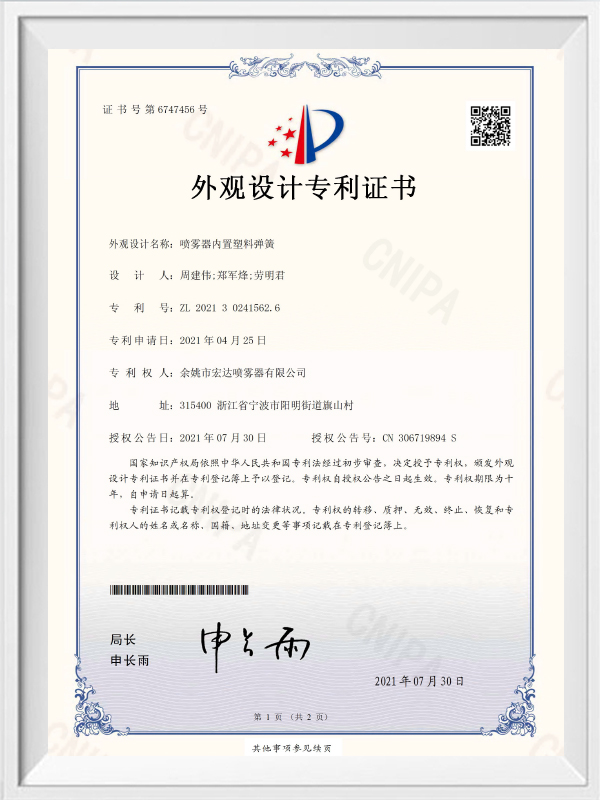

Inside Spring Lotion Pump is that the metallic spring is positioned internally within the pump’s shaft structure and is completely isolated from the liquid being dispensed. In contrast, an external spring pump typically houses the spring either above or adjacent to the product flow path, where it may come into direct contact with the formulation—especially in the case of more liquid or low-viscosity products. This physical isolation prevents chemical reactions between the product and the spring, such as oxidation, rusting, or metallic leaching. Formulations that contain high concentrations of water, acids, plant extracts, or essential oils are particularly prone to inducing metal corrosion, which not only affects the aesthetic appearance of the product but can also compromise its chemical composition, alter its scent, or cause unwanted discoloration. Zhejiang EAED Technology Development Co., Ltd., formerly known as Yuyao Hongda Sprayer Co., Ltd., adopts advanced internal spring engineering across its Inside Spring Lotion Pump line. The company has invested in high-precision tooling and part integration to ensure that the spring remains completely sealed from the product channel, minimizing contamination and maintaining consistent dispensing quality over prolonged usage cycles.

Air exposure and metallic contact are two common factors that accelerate the degradation of skincare and cosmetic formulas. When a product regularly contacts a metal spring in an external design, it may absorb trace ions or undergo accelerated oxidation due to the catalytic properties of metal. This process is especially detrimental for formulations containing antioxidants, vitamins (like Vitamin C or E), and natural extracts, which are inherently sensitive to such catalytic degradation. In Inside Spring Lotion Pumps, the design eliminates this point of contact. The fluid pathway is constructed from chemically inert plastic materials such as PP (polypropylene) or PE (polyethylene), which do not interact with the formula. As a result, the shelf life of the product is significantly extended, and its efficacy remains intact over time. This is especially relevant for brands marketing premium serums, anti-aging products, or organic formulations that avoid synthetic preservatives. Zhejiang EAED Technology Development Co., Ltd. has developed multiple models of Inside Spring Lotion Pumps with different dosage outputs and chamber configurations to cater to clients that require extended product longevity. Through cooperation with both domestic and international skincare brands, EAED aligns its pump designs with the packaging needs of high-sensitivity formulas to preserve their potency from manufacturing through to end-user application.

Another overlooked aspect of external spring pumps is the potential for microbial contamination. In some designs, the spring chamber is not perfectly sealed and can allow moisture or product residue to enter, creating an environment where bacteria or mold can grow. Even if the spring is not immersed in the product, residual material can accumulate around the spring, especially in pump models that are not self-sealing or that rely on older gasket technologies. By contrast, Inside Spring Lotion Pumps offer a cleaner and more hygienic structure. The spring is embedded deep within a plastic housing and protected by one-way valves and precision-fit gaskets that prevent fluid backflow. This design significantly reduces the potential for microbial growth inside the actuator or pump mechanism. This feature is crucial for preservative-light or preservative-free formulas, which are increasingly popular among eco-conscious and health-aware consumers. As a leading Inside Spring Lotion Pump Manufacturer and Supplier, Zhejiang EAED Technology Development Co., Ltd. implements stringent quality assurance protocols in its production processes. EAED performs microbial resistance testing and backflow prevention evaluations to validate the hygienic performance of its internal spring pump designs. The company’s pursuit of clean manufacturing environments and high-precision component assembly ensures that each unit meets international hygiene expectations.

In external spring designs, the accumulation of rust or product residue around the spring mechanism can eventually impair pump performance or lead to unsightly discoloration, especially in transparent or semi-transparent packaging. A visible metal spring that degrades over time not only compromises visual branding but also sends a negative signal to end users about product safety. Inside Spring Lotion Pumps maintain their aesthetic appeal by keeping all mechanical elements hidden and sealed. There is no exposure of metal parts to moisture or external air, which keeps the actuator and collar areas clean and attractive. Furthermore, because the internal spring is better protected from mechanical wear and environmental stress, the pump maintains consistent force and return speed throughout its life cycle. Zhejiang EAED Technology Development Co., Ltd., located in the historic and industrial hub of Yuyao, ensures this level of reliability through complete fine management and high-precision injection molding. EAED’s design engineers conduct cycle testing on internal spring pumps to ensure that even after thousands of uses, the return mechanism remains responsive and the output volume stable.

Brands that formulate products with minimal preservatives, organic ingredients, or sensitive actives often require packaging that supports the formula’s integrity. Inside Spring Lotion Pumps are particularly well suited to this segment because of their inert material interface and reduced contamination risks. Whether for baby care products, clinical-grade moisturizers, or plant-based serums, these pumps provide the level of protection required to preserve both safety and brand value. Zhejiang EAED Technology Development Co., Ltd. plays a key role in supporting these market segments by providing customizable Inside Spring Lotion Pumps that conform to various formulation sensitivities. Through collaboration with R&D teams of high-value skincare brands, EAED provides technical documentation, test samples, and compatibility assessments to help clients choose the right pump architecture based on pH, viscosity, and active ingredient profiles.

From a regulatory and marketing standpoint, Inside Spring Lotion Pumps contribute to improved consumer confidence and compliance with safety regulations. Packaging that eliminates the chance of metallic leaching or microbial ingress is easier to pass through FDA, EU Cosmetics Regulation (EC) No 1223/2009, and other international safety standards. Consumers are also increasingly educated about what goes into their products and often seek packaging solutions that protect formulation purity. Zhejiang EAED Technology Development Co., Ltd. integrates its manufacturing excellence and compliance strategy to support clients in navigating the increasingly strict regulatory landscape. With clients across Europe, Asia, and North America, EAED understands the documentation and testing needed to assure both regulatory bodies and end-users of a pump’s safety profile.

English

English русский

русский Français

Français Español

Español italiano

italiano