What Are the Most Common Applications for Full Plastic Pumps in Commercial Packaging Solutions?

Full Plastic Pumps have become indispensable in the personal care and cosmetics sectors, where packaging not only preserves the product’s integrity but also enhances user experience. Products such as hand soaps, body lotions, facial cleansers, shampoos, conditioners, and sunscreens frequently utilize full plastic pumps due to their excellent chemical compatibility and ability to deliver consistent dosage. The plastic materials used in these pumps—often polypropylene or polyethylene—are selected for their inertness, ensuring that no chemical reactions occur between the pump components and sensitive cosmetic formulations. The design flexibility of full plastic pumps allows cosmetic brands to customize color, shape, and texture, aligning packaging aesthetics with brand identity. This is especially important in a highly competitive market where packaging contributes significantly to consumer perception and product differentiation. The pumps’ smooth actuation and reliable dispensing help maintain the product’s quality by minimizing contamination risks and waste. Zhejiang EAED Technology Development Co., Ltd., based in the historic city of Yuyao and leveraging proximity to Shanghai and Ningbo ports, integrates these demands into its manufacturing. EAED collaborates closely with both domestic and international cosmetic brands, supplying pumps that meet rigorous quality standards and aesthetic expectations. Their commitment to continuous innovation and fine management ensures that their full plastic pumps support brand success through reliable, visually appealing, and sustainable packaging solutions.

The pharmaceutical and healthcare industries require packaging solutions that prioritize safety, precision, and sterility. Full Plastic Pumps are ideal for dispensing topical medications, antiseptic solutions, gels, and certain liquid pharmaceuticals due to their inert construction, which prevents interaction with sensitive active ingredients. These pumps help maintain the efficacy of drugs by eliminating corrosion risks and reducing contamination potential—critical factors in healthcare environments. Precision dosing is paramount in pharmaceutical applications, where the amount dispensed can directly impact treatment outcomes. Full plastic pumps offer repeatable and accurate volume delivery, complying with stringent regulatory standards governing materials in contact with medicinal products. The hygienic design of these pumps supports infection control measures, a vital consideration in clinical and hospital settings. Zhejiang EAED Technology Development Co., Ltd. applies advanced quality management systems and material selection protocols to produce pharmaceutical-grade full plastic pumps. Their ability to meet international certification standards makes them a preferred partner for pharmaceutical companies seeking reliable and compliant dispensing technologies. EAED’s extensive experience with medical-grade products and close client cooperation ensures pumps that fulfill safety, accuracy, and regulatory demands globally.

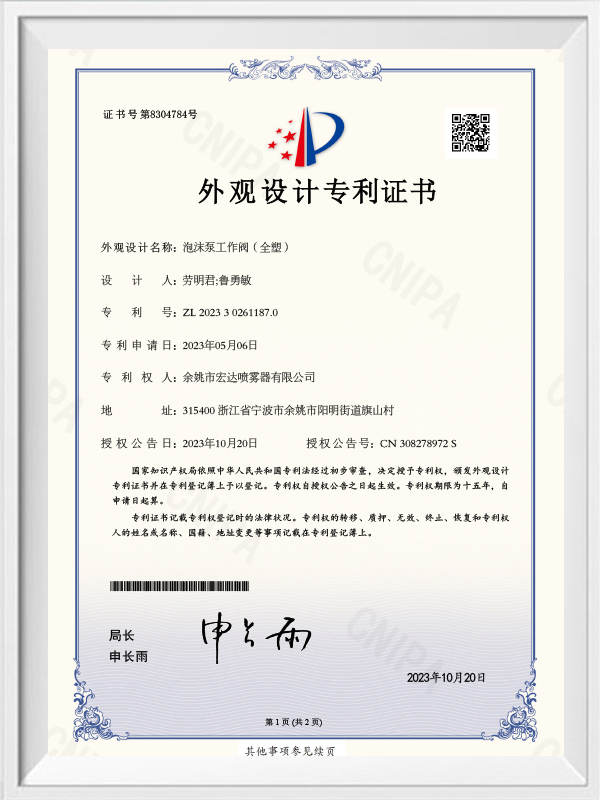

The surge in demand for hygiene and sanitation products has positioned full plastic pumps as an essential component in household cleaning and disinfection packaging. Products like liquid hand sanitizers, surface disinfectants, detergents, and multipurpose cleaners often contain harsh chemicals such as alcohol, bleach, and strong surfactants, which can corrode metal components traditionally used in pumps. The full plastic pump’s corrosion-resistant construction prevents chemical degradation and pump failure, extending the product’s shelf life and usability. Beyond chemical compatibility, these pumps provide ease of use and controlled dispensing, which enhances consumer safety and satisfaction. Many formulations require specific output volumes to ensure effective cleaning or disinfection without waste or accidental overuse. Full plastic pumps can be engineered with variable dosage volumes and even foaming capabilities to adapt to different product characteristics and consumer preferences. Zhejiang EAED Technology Development Co., Ltd.’s expertise in material science and molding technology enables it to develop pumps tailored for aggressive chemical environments. Their pumps undergo rigorous testing to guarantee durability and performance under exposure to disinfectants and detergents. EAED’s focus on continuous product improvement supports manufacturers in delivering high-quality, dependable household hygiene solutions that align with current health and safety expectations.

Though less prevalent than in personal care, full plastic pumps have found niche applications in the food and beverage industry, especially for dispensing liquid condiments, syrups, sauces, and liquid sweeteners. Food safety is paramount, so pumps must be manufactured from FDA-compliant or equivalent food-grade plastics that do not leach harmful substances or alter the product’s taste or odor. The all-plastic construction prevents corrosion and facilitates cleaning, which is essential for maintaining hygiene standards in food packaging. These pumps provide controlled dosing, which helps consumers dispense the right amount of product, reducing waste and improving convenience. Their leak-proof sealing also prevents contamination and preserves freshness. Zhejiang EAED Technology Development Co., Ltd. leverages its advanced molding capabilities and material knowledge to supply pumps suitable for food-grade applications. Their pumps are designed to comply with stringent food safety regulations and support manufacturers’ efforts to produce consumer-friendly packaging solutions. By integrating sustainability and reliability, EAED enables food and beverage brands to enhance their product presentation and functionality.

In industrial and specialty chemical sectors, full plastic pumps are preferred for dispensing adhesives, lubricants, solvents, coatings, and other reactive or corrosive substances. The absence of metal components eliminates corrosion risks and contamination, critical for maintaining product integrity and ensuring safety during handling. Industrial applications often demand pumps that can withstand harsh environments, including exposure to extreme temperatures and aggressive chemical formulations. Full plastic pumps offer chemical resistance and robustness, while customizable features allow tailoring dosage volumes and dispensing speed to specific operational requirements. Zhejiang EAED Technology Development Co., Ltd. supports industrial customers by offering durable, chemical-resistant pumps engineered for reliability in demanding conditions. Their rigorous quality control and customization capabilities make them a dependable partner for companies needing precision dispensing in chemical processing, manufacturing, and maintenance applications. EAED’s focus on innovation and quality ensures pumps that contribute to operational efficiency and product safety.

Airless packaging technology is critical for products sensitive to oxidation and contamination, such as high-end skincare serums, vitamin formulations, and pharmaceutical creams. Full plastic pumps, free from metal springs and components, are optimal for airless systems that dispense product through piston or bag-in-bottle mechanisms. These pumps help extend product shelf life by preventing air exposure, which can degrade active ingredients and reduce product effectiveness. Their design also supports hygienic dispensing and user convenience by delivering consistent doses without product backflow or leakage. Zhejiang EAED Technology Development Co., Ltd. manufactures full plastic pumps specifically designed for compatibility with airless packaging. Their expertise in precision molding and assembly enables them to produce pumps that meet stringent functional and aesthetic requirements. EAED’s solutions help brands protect their formulations, meet consumer expectations for quality, and comply with evolving packaging sustainability standards.

English

English русский

русский Français

Français Español

Español italiano

italiano