What Are the Key Functional Benefits of Using an Outside Spring Lotion Pump in Cosmetics and Personal Care Applications?

The foremost advantage of the

Outside Spring Lotion Pump is its ability to prevent contamination and oxidation of the product inside the container. In conventional lotion pump designs, the spring is situated within the fluid pathway, which means that the product—whether it be lotion, serum, cream, or gel—comes into contact with the metal spring during every dispensing action. This contact may seem harmless in some instances, but it can significantly affect the stability and longevity of sensitive formulations. Certain ingredients, especially natural extracts, organic acids, and vitamins like Vitamin C and E, are prone to oxidation when exposed to metals or even minor impurities. Oxidation not only alters the color and smell of the product but also degrades its active ingredients, thereby compromising its effectiveness. In contrast, the Outside Spring Lotion Pump is engineered to eliminate this risk. By placing the spring outside the product chamber, it ensures that the metal never comes into contact with the product. This physical separation acts as a barrier against corrosion and leaching, which could otherwise introduce metallic ions or contaminants into the formulation. This feature is especially useful for premium and natural skincare products that avoid synthetic preservatives or stabilizers and rely on clean, reactive-free environments to maintain their shelf life. Zhejiang EAED Technology Development Co., Ltd. leverages this design benefit as part of its commitment to high-quality dispensing technology. As a leading Outside Spring Lotion Pump Manufacturer, EAED emphasizes product integrity and functionality. Located in the ancient city of Yuyao and backed by advanced engineering teams, EAED supports brands around the globe that formulate sensitive products, enabling them to offer cleaner, more stable skincare solutions to their customers. This technical advantage translates into increased consumer trust, fewer returns, and greater product efficacy—key elements in today’s competitive personal care market.

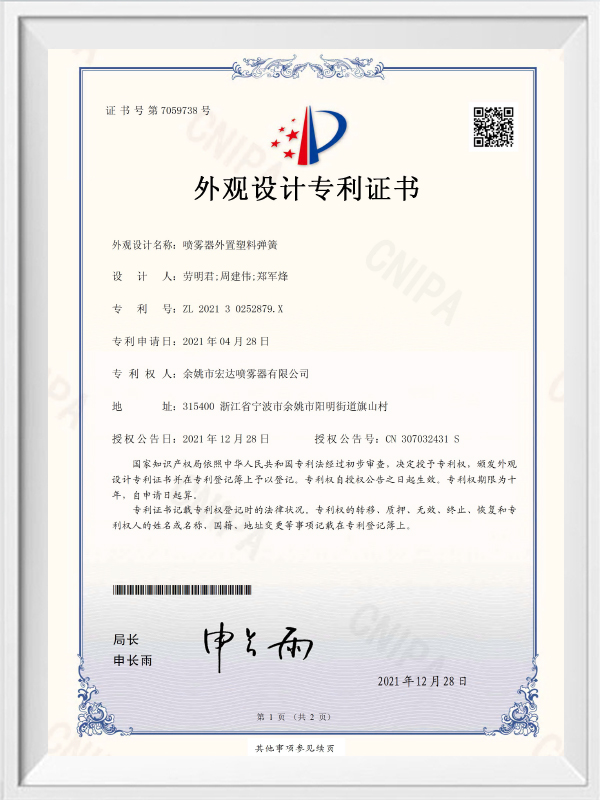

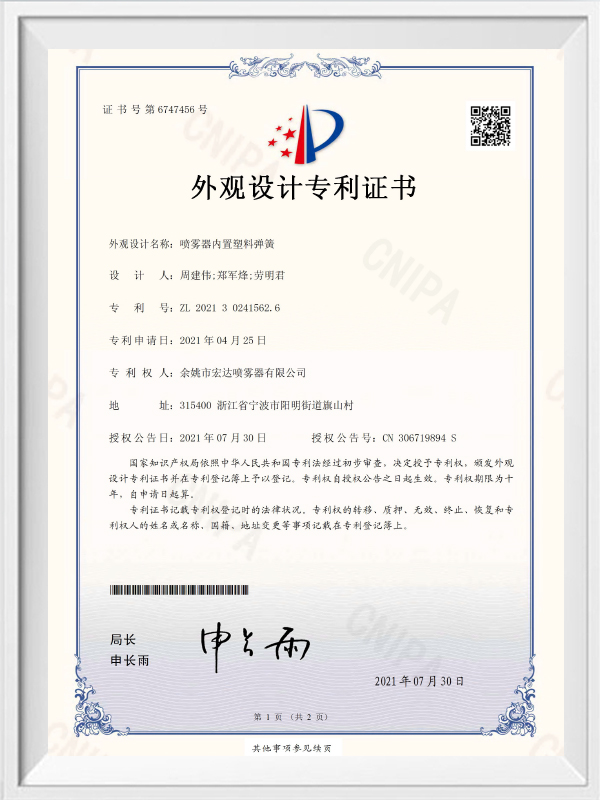

In the cosmetics and personal care industry, where products are directly applied to the skin, hygiene is not optional—it’s a critical requirement. Consumers increasingly demand products that not only deliver results but also guarantee safety and cleanliness from the moment of packaging to the last dose dispensed. The Outside Spring Lotion Pump delivers on this front with a structural design that eliminates internal metal exposure to the product, thereby significantly reducing the possibility of microbial growth or chemical contamination. The absence of internal springs in the flow path minimizes the number of components that could harbor residue or react with the formula, leading to a much cleaner dispensing experience. In formulations containing minimal or no preservatives—such as natural moisturizers, baby care lotions, or high-purity serums—the risk of bacterial contamination is heightened. Conventional pumps can become a breeding ground for bacteria if the spring becomes coated with product over time. The external positioning of the spring in EAED’s Outside Spring Lotion Pump ensures that the internal flow path remains free from metal and unnecessary joints or mechanical parts that could become unsanitary. This increases the overall hygiene level of the dispensing system and aligns with GMP (Good Manufacturing Practice) standards often required in the cosmetic and pharmaceutical industries. Zhejiang EAED Technology Development Co., Ltd., formerly Yuyao Hongda Sprayer Co., Ltd., integrates this safety innovation into all its Outside Spring Lotion Pump models. The company has built a reputation as one of China’s top pump suppliers by emphasizing product cleanliness, high production standards, and detailed engineering. Based in Yuyao, EAED benefits from access to advanced manufacturing and logistical infrastructures. Their commitment to hygiene and customer safety extends throughout the design, testing, and packaging phases, ensuring that their products consistently meet the highest standards demanded by international clients.

One of the essential performance metrics in packaging for cosmetics and personal care products is durability—both in terms of mechanical reliability and chemical resistance. Outside Spring Lotion Pumps excel in this area due to their distinct construction. Unlike traditional pumps, where the spring mechanism is immersed within the product and often subjected to constant moisture and chemical exposure, the external spring design isolates this component from the liquid, preventing wear, corrosion, and mechanical failure. This separation is not merely a convenience; it’s a vital safeguard. Springs made from stainless steel or other metal alloys can degrade over time when exposed to water-based or acidic products, leading to rust, decreased actuation responsiveness, and potential contamination. However, when the spring is placed outside the fluid path, it remains dry and unaffected by the product’s chemical composition. This contributes to a longer functional life for the pump and greater confidence for end users who expect packaging that works reliably from first to last use. In practical terms, this design translates to fewer pump failures, consistent output strength, and lower replacement or complaint rates—particularly important for brands that operate at scale or target premium markets. For example, if a user purchases an expensive facial serum or body lotion, a malfunctioning pump could lead to frustration and damage the brand's reputation. A high-quality Outside Spring Lotion Pump prevents these risks. Zhejiang EAED Technology Development Co., Ltd., as a reputable manufacturer of Outside Spring Lotion Pumps, incorporates materials selection, fatigue testing, and stress analysis into its product development processes to ensure superior durability. Backed by decades of experience in precision mold production and assembly in Yuyao, EAED continues to offer pumps that meet or exceed global durability standards. Their pumps are particularly favored in high-frequency use environments such as spas, clinics, or daily skincare routines—demonstrating their long-term value and engineering superiority.

Consistency and precision in product dispensing are crucial for both user experience and brand quality. When a consumer uses a lotion or serum, they expect the same amount to be dispensed with each press, every time. This becomes even more critical for high-potency or dosage-sensitive products, such as anti-aging serums, retinol creams, or active-ingredient-rich lotions. The Outside Spring Lotion Pump is uniquely suited to deliver such consistent performance due to its refined mechanics and external spring setup. Traditional pumps, especially those with internal springs, can suffer from uneven resistance or degraded actuation over time as the internal components interact with thick or reactive formulations. In contrast, the Outside Spring Lotion Pump provides smooth actuation, uniform pressure, and consistent flow without internal contamination or mechanical fatigue caused by product interaction. Because the spring does not interfere with the fluid path, the internal volume of the pump remains unobstructed, allowing for a predictable and repeatable amount of product with each use. This uniformity is not just beneficial for consumer satisfaction—it’s also critical for regulatory compliance and branding. For example, skincare lines that advertise a 0.5ml or 1ml dosage per pump must deliver accurately to maintain brand integrity and avoid over- or under-dosing, which could impact the effectiveness or perceived value of the product. The Outside Spring Lotion Pump supports such claims by offering precision manufacturing tolerances and optimized flow channels. Zhejiang EAED Technology Development Co., Ltd. understands the importance of consistent user experience in competitive markets. Their advanced molding capabilities and in-house quality control systems ensure each pump meets strict dispensing accuracy standards. Working with global skincare and cosmetics brands, EAED fine-tunes pump design specifications based on viscosity, fill volume, and end-use environment to ensure that consumers receive the correct amount of product every time. This professional commitment has made EAED a respected Outside Spring Lotion Pump Supplier not just in China, but across international markets.

English

English русский

русский Français

Français Español

Español italiano

italiano